Mecasem is your essential quality service provider. We carry out mechanical tests, fatigue tests, durability tests, metallographic examinations and chemical analyses, climatic tests, ageing tests, heat treatments and non-destructive tests. We have NadCap accreditation for mechanical testing, fatigue testing and machining services. We also machine our own test specimens for a complete turnkey service. Whatever your field of activity – aeronautics, defence, transport, construction and civil engineering (Infrastructure & Housing), Energy, pharmaceutical and medical, food processing ou industrial supplies– Mecasem offers industrial tests (mechanical tests, fatigue tests, durability tests) to meet your specific needs.

MACHINING

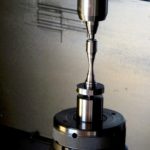

Mecasem has specialised in preparing test specimens since 1980.

This expertise is recognised by demanding customers in the leading sectors of activity in aeronautics, nuclear, metallurgy, medical, etc.

QUALITY AND APPROVALS

The quality level is guaranteed by our ISO 9001, ISO 9100, Nadcap and Cofrac EN 17025* approvals and certifications. Our machining operators are trained and qualified in the latest technological developments. Guaranteed traceability.

SHORT LEAD TIMES

Our machining workshops integrated within our laboratories and our inventory of machines equipped with all the appropriate machining resources provide maximum flexibility and very responsive machining lead times. Our independent testing laboratories have established partnerships with the main inspection bodies: BV, SGS, TUV, Lloyds’ Register, etc.

*List of sites and scopes available on www.cofrac.fr

INDUSTRIAL TESTING

PREPARATION OF MECHANICAL, METALLURGICAL AND CORROSION TEST SPECIMENS

Cylindrical, prismatic, resilient, folded specimens.

Specific specimens for fatigue, CTOD, K1C.

Machining of steel, aluminium, titanium, inconel, composites.

- QUOTATION: STUDIES AND SOLIDWORKS CAD

- CUSTOM MACHINING – SPECIAL MECHANICAL ASSEMBLIES

- 40 YEARS OF INDUSTRY EXPERTISE

CONTRACT THROUGHPUT

Range of high capacity horizontal and vertical sawing machines

Sampling for destructive tests.

Workshop cutting and sawing of all kinds of metals.

- WIRE EROSION (Electro Discharge Machining)

- CAD – SOLIDWORKS

Capacity: 5N to 3000kN Temperature: -269° to +1000°C

Fatigue

Durability limit (bending, rotation, elongation/compression

Oligocyclic tests

Cracking speed da/dN

Priming criteria

Tensile strength and compression tests

Tensile strength tests as per ISO 6892-1 Methods A and B

Test specimens or large parts

Special assemblies designed and manufactured for all types of applications

Tests on screws, nuts

Testing on strips, wires

Bend tests

Adapted to all types of ASTM or ISO standards

Resilience testing

As per EN and ASTM standards

Transport

Simulation of vehicle entry/exit using a KUKA robot

Tests on seats

Reproduction of movements measured using a pressure mat

Seat durability tests on benches with 2 or 3 axes

Accelerated backrest durability tests

Durability test of upholstered cushion padding.

Durability tests on sub-assemblies

All types of mechanical tests with servo-controlled force or displacement.

Movement reproduction in durability tests under different climatic conditions

Tests following customer specifications, creation of special test rigs

Tilting durability of vehicle rear seats with associated measurements and characteristics

Seatbelt unwinding/retracting durability

Cycling of all types of switches with measurements (contact resistance or leakage current)

Vibration test

All sine wave profiles up to 250 Hz

Random profiles

Reproduction of road profiles from recordings

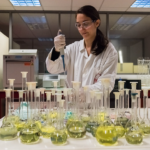

Chemical analysis in laboratory and on site

Elemental analysis by plasma or arc emission spectrometry

Elemental analysis on all metal alloys

C&S-specific analyser by combustion and infrared detection

On-site arc spectrometry (PMI) analyser

Corrosion tests in aqueous environment

Hardness testing

Vickers

Brinell

Rockwell

Microhardness

Analyses on all metals and alloys

Tests of all types under

Constant temperatures

Tests in moist heat

Rapid temperature variations

Thermal shocks

Temperature ranges

From – 80 °C to + 220 °C

Humidity:

from 10% to 98%

Chamber dimensions:

from 450 x 330 x 330

to 1,100 x 1,100 x 1,100

Atmospheric corrosion tests

Saline atmosphere (salt mist)

Dissolved sulphur atmosphere

Tests in H2S, SO2 or mixed gas atmosphere

Stress corrosion testing

Corrosion tests in acidic environment

Radiography

Using X-rays or gamma rays, we carry out radiography on parts and record their images on film.

200 kV and 300 kV X-ray tubes

All metals (up to 40mm steel) and non-metallic materials.

E.g welded assemblies or castings

Ultrasound

All metals (no thickness limit)

Full-penetration welded assemblies

Thickness measurement on tank

Aeronautical composites

Rolled/Forged products (bars, sheets)

Moulded products

Dye penetration testing (Nadcap accredited)

All types of materials

Welded assemblies

Machined and ground mechanical parts

Castings

Magnetic resonance imaging (Nadcap accredited)

Applications

Ferromagnetic materials

Aeronautical parts

Welded assemblies

Machined, ground or maintenance mechanical parts.

On-site applications: :

boiler works, metal construction, material supplier, refineries, petrochemicals.

Workshop applications:

on fixed bench: automotive and aeronautics parts.

TESTS ON YOUR PARTS UNDER PRESSURE AND AT TEMPERATURE

Our experts are familiar with the latest standards and regulations, audited annually by an independent certified body. Our technical team adapts to any specific procedure.

We help you define your own test protocol. We have a wide range of test facilities and services, video data recording, monitoring of physical characteristics (pressure, temperature, flow rate, etc.), electronic signature of test reports and data transmission.

Leak detection – Burst tests:

– Hydraulic pressure tests (100 bar)

– Pneumatic pressure tests (33 bar)

– Helium leak detection, specify range 1.10-8 mbar.L/s

– Hydrogen leak detection, specify range 1.10-6 mbar.L/s

Test report:

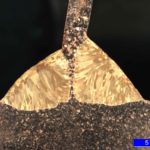

Example of a material defect detected on a non-compliant cylinder body

Leak test of a threaded sleeve welded on a stainless-steel pipe, for the automotive sector

Leak test of a threaded sleeve welded on a stainless-steel pipe, for the automotive sector

2 Test pools:

– Dimensions: length 4 metres, width 1.5 metres, depth 2 metres

– Dimensions: length 2 metres, width 1.5 metres, depth 2 metres

Mechanical machining:

Production of flanges or special sub-assemblies appropriate to your products and ensuring effective seals during tests

Example of the design and construction of the air supply system and tooling providing the seal

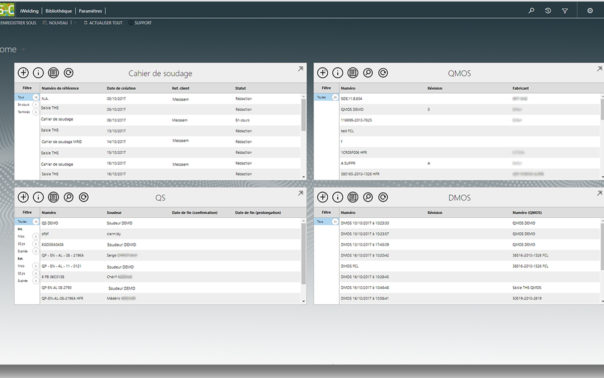

ONLINE TEST REQUESTS

Fulfil your requests for tests on welded assemblies

The My Self-Control application simplifies and speeds up processing your quotations for all your standardised weld inspections. You can digitise and so manage your welding documentation (QMOS, QS) more easily online using the iWelding application and complete your quotation requests in a few clicks.

Test reports in digital format

Your test reports are sent in PDF format by e-mail with a secure electronic signature recognised by COFRAC and regulatory bodies (NF EN ISO/IEC 17025, LAB REF 02 and LAB GTA 09).

OUR LITTLE EXTRAS THAT MAKE THE DIFFERENCE

An 8,000 m2 production and testing site located in Alsace at the heart of Europe

Vehicles equipped for on-site interventions throughout France and in other countries

Mecasem shuttle service for your measuring instruments and test specimens

Tour 1 : Strasbourg – Mulhouse – Allemagne – Belfort – Montbéliard – Besançon

Tour 2 : Marnaz – Grenoble – Lyon – Le Creusot – Besançon

Tour 3 : Marnaz – Vallée de l’Arve – Annecy – Marnaz

Tour 4 : Besançon – Saint-Louis – Mulhouse – Besançon

Tour 5 : Zone Lyon

They trust us